Cold Weather Concrete Repair Tips for Pueblo

Concrete Repair Pueblo

Winter presents unique challenges for concrete repair in Pueblo, where temperatures regularly drop below freezing and intense sun creates dramatic daily temperature swings. Understanding how cold weather affects concrete repair processes helps homeowners and contractors achieve successful results despite harsh conditions. Pueblo’s semi-arid climate combines freezing nights with sunny days, creating opportunities for repairs when properly timed and executed. The key lies in recognizing when conditions permit repairs and implementing appropriate cold-weather techniques. These practical tips enable effective concrete repair throughout Pueblo’s winter months while ensuring long-lasting, quality results.

Understanding Cold Weather Concrete Challenges

Cold weather is defined as any three consecutive days where the average temperature falls below 40 degrees Fahrenheit by the American Concrete Institute (ACI). Pueblo consistently has cold weather throughout the months of November, December, January, February, and March. The slower chemical reaction in cold weather limits how fast and strongly concrete will cure and develop its final strength. When temperatures fall below 40 degrees, the chemical reaction slows down dramatically. If the concrete freezes prior to reaching a minimum of 500 PSI, the concrete will be permanently damaged. As the water within fresh concrete freezes, it expands and disrupts the internal structure of the concrete. The expanding water also compromises the bond strength of the repaired section. All of the properties in Aberdeen and Belmont face these issues each winter.

Guidelines for Scheduling Winter Repairs

Using Sunshine to Your Advantage

Although Pueblo has cold air temperatures throughout the winter, there are many days with direct sunlight that create favorable conditions for performing repairs. Since direct sunlight can increase the temperature of concrete surfaces 15 to 25 degrees above the air temperature, there are times when the air temperature could be 30 degrees, and the concrete surface will be 45 to 55 degrees. Therefore, there are opportunities to successfully perform repairs when you coordinate your repair to occur when the concrete surface is warm enough to support the repair.

Start your repairs in the middle of the morning once the concrete surface has warmed up from the sun, and complete your work by early afternoon so the repair material will have ample opportunity to develop some of its initial curing before the temperature drops in the evening. Any property in Pueblo with a southern exposure will get maximum sun exposure to perform your repairs. Open exposures such as those found in University Park and Eagleridge offer ideal sunlight conditions to perform repairs in the winter. We schedule winter repairs to take advantage of these natural benefits.

Following Weather Forecasts

Before you start any repairs, check the extended weather forecast to determine if the next few days will have temperatures above freezing. The repair material requires at least 24 to 48 hours above 40 degrees to develop the necessary initial strength. One day of good weather followed by freezing temperatures during the night is bad for any recent repairs. Avoid starting repairs if the forecast indicates that the temperature will drop below 40 degrees within 48 hours after completing the repairs.

Take note of both the overnight lows and daytime highs when planning your repair projects. Pueblo tends to have cold nights followed by warmer days. However, Arctic air masses can cause prolonged periods of below-freezing temperatures that require delaying repairs. We continuously follow multiple forecasting resources to enable us to make educated decisions regarding the best timing for winter repairs.

Preparing Surfaces in Cold Weather

Cleaning the surface to be repaired is essential before applying any repair materials. Removing ice, snow, and frost from the surface is necessary to allow the repair material to adhere properly and to prevent introducing excessive amounts of moisture into the repair. Use brooms or leaf blowers instead of water to clean the surface when the temperatures are near freezing. Water will create additional ice problems.

Do not attempt to repair any frozen concrete until it has completely thawed out. If you need to speed up the thawing process, consider using heating blankets or propane heaters. Ensure the substrate temperature reaches at least 40 degrees before applying any repair materials. Use an infrared thermometer to obtain an accurate reading of the surface temperature. There are occasions during the Pueblo winters when emergency repairs must be completed, and heated enclosures may be required to prepare the surface.

Choosing Appropriate Materials for Cold Weather

Repair Materials Formulated for Cold Weather

Repair materials that are specifically formulated to function in cold weather perform much better than standard repair materials in Pueblo’s winters. These specialized repair materials contain accelerating agents that promote curing even at colder temperatures. Cold-weather patching compounds are more workable at cooler temperatures than standard compounds, yet they achieve adequate strength quickly. The cost of utilizing proper materials prevents costly repairs.

Carefully read the product label to confirm the recommended application temperature range for each type of repair material. Some types of repair materials can be applied at temperatures as low as 25 degrees, while others require temperatures of 40 degrees or higher. Store the repair materials in a heated space before using them to maintain their workability. Repair materials stored in cold conditions are difficult to mix and apply.

Avoiding Standard Summer Products

Repair materials used to repair moderate-temperature concrete do not work in cold weather. The curing process is slowed down in cold temperatures, and the materials do not develop sufficient strength. Although the repair material appears to have set, it lacks the necessary bond strength and durability. Utilizing improper repair products wastes valuable time and money and does not resolve the original issue.

There are instances when residents of Pueblo have experienced failed repairs as a result of choosing the wrong repair products in the absence of cold-weather products. While it may be tempting to utilize readily available repair products in lieu of purchasing proper cold-weather products, doing so results in disappointing outcomes. Delaying the repair until you have acquired the correct materials will produce superior results compared to hurrying the repair with improper products. We carry the necessary repair materials for winter repair applications.

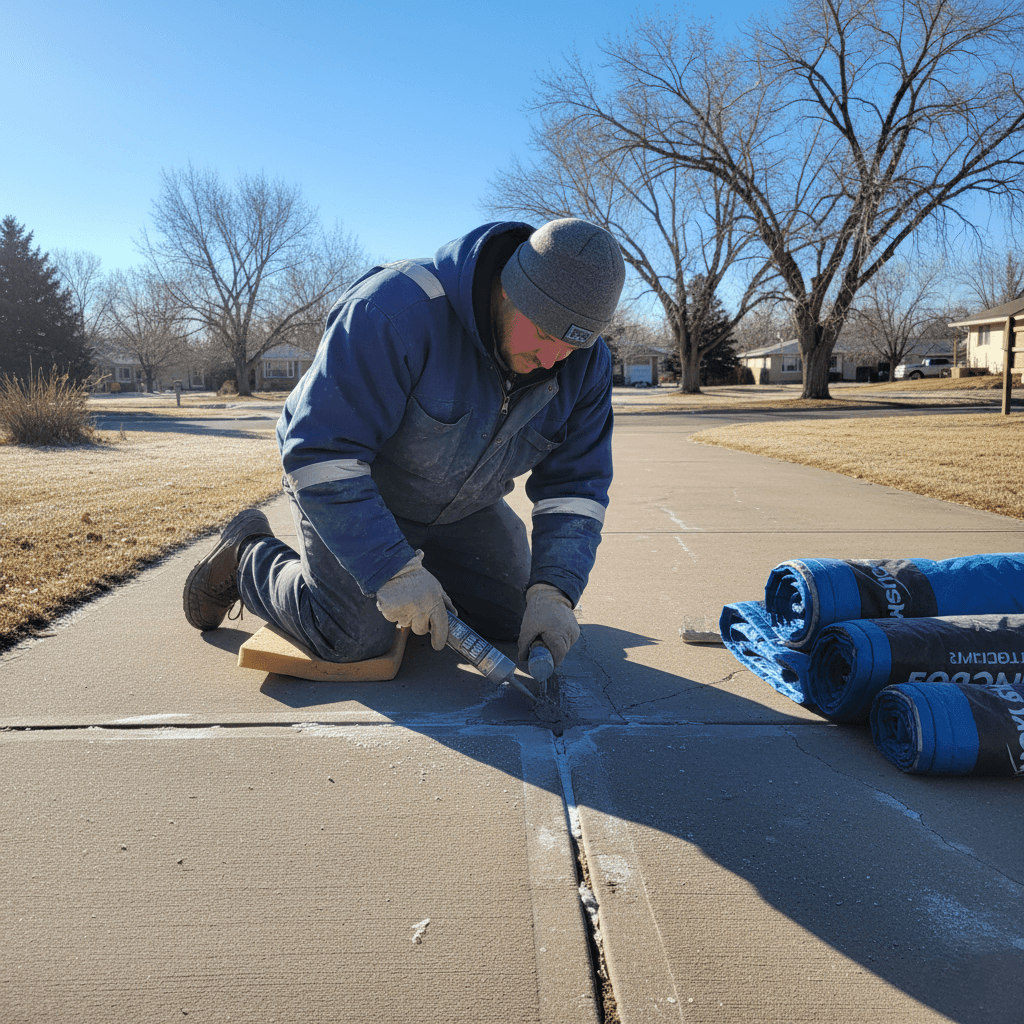

Repair Techniques for Cracks

Smaller crack repairs are performed more successfully in cold weather than larger structural repairs. Due to the smaller volume of repair material, the repair material cures more rapidly and requires less heat retention. Before repairing a crack, remove all debris and loose material from the crack. Allow the crack to dry completely before filling the crack, as moisture freezing in the repair material causes the repair to fail.

Use cold-weather-rated flexible crack sealants to repair small cracks. Flexible sealants remain pliable in cold temperatures and bond well to the surrounding concrete despite thermal contraction. Many rigid fillers fail in the winter due to the thermal movement that stresses the repair material. Neighborhoods in Pueblo with flexible repair methods, such as Mesa Junction and Belmont, benefit from the ability of the repairs to flex in response to extreme temperature fluctuations. Fill the crack in thin layers rather than trying to fill the entire length of the crack in one layer.

Protecting New Repairs

Methods of Insulation

Once you have completed a repair, cover the repair with insulating blankets to retain heat. The concrete’s natural heat of hydration, combined with retained solar warmth, provides sufficient heat for curing. Straw bales, foam insulation boards, or commercial curing blankets are effective insulating mediums. Secure the blankets in place to prevent them from being blown away by the wind overnight.

Leave the insulation in place for a minimum of 48 to 72 hours, depending on the ambient temperature. Slowly decreasing the temperature will prevent thermal shock that can cause cracking in the repair. Remove the insulation during warm afternoon periods and replace it before the temperature drops in the evening. Residents of Pueblo who require winter repairs will benefit from the simple yet effective protection provided by this method. The cost associated with the purchase of insulating materials is a fraction of the cost of repairing failed repairs.

Temporary Heated Enclosures

In cases where extremely cold temperatures are present, repairs may require a temporary heated enclosure. A heated enclosure can be created by covering the repair area with plastic sheeting and using propane heaters to maintain a temperature above freezing. Heated enclosures provide the option to perform repairs during prolonged periods of sub-freezing temperatures. The increased costs associated with heated enclosures are justified by the fact that the repair cannot be delayed.

Closely monitor the temperature within the enclosure to prevent overheating that can cause rapid drying of the repair material. Optimal curing temperatures for most repair materials range from 50 to 70 degrees. Proper ventilation is necessary to prevent the buildup of carbon monoxide gas produced by the propane heaters. We utilize heated enclosures for critical repairs that must be completed during unfavorable winter conditions in Pueblo.

De-Icing Salts

Never apply de-icing salts to recently completed repairs or to newly installed concrete surfaces. De-icing salts penetrate the surface of the concrete and inhibit the curing process, while also causing internal damage to the concrete. Additionally, de-icing salts enhance the rate of freeze-thaw deterioration by allowing water to penetrate deeper into the concrete. The damage caused by de-icing salts often exceeds the damage that was originally addressed by the repair.

Utilize sand, kitty litter, or other non-chemical traction materials to provide traction on concrete surfaces during the winter. These alternatives provide safe traction on the surface of the concrete without causing damage to the surface. Mature concrete is also susceptible to repeated exposure to de-icing salts; utilizing alternative traction materials extends the lifespan of the concrete. Residents of Pueblo benefit from extending the lifespan of their concrete by avoiding de-icing salts. We educate residents of Pueblo regarding the long-term effects of using de-icing salts on concrete surfaces.

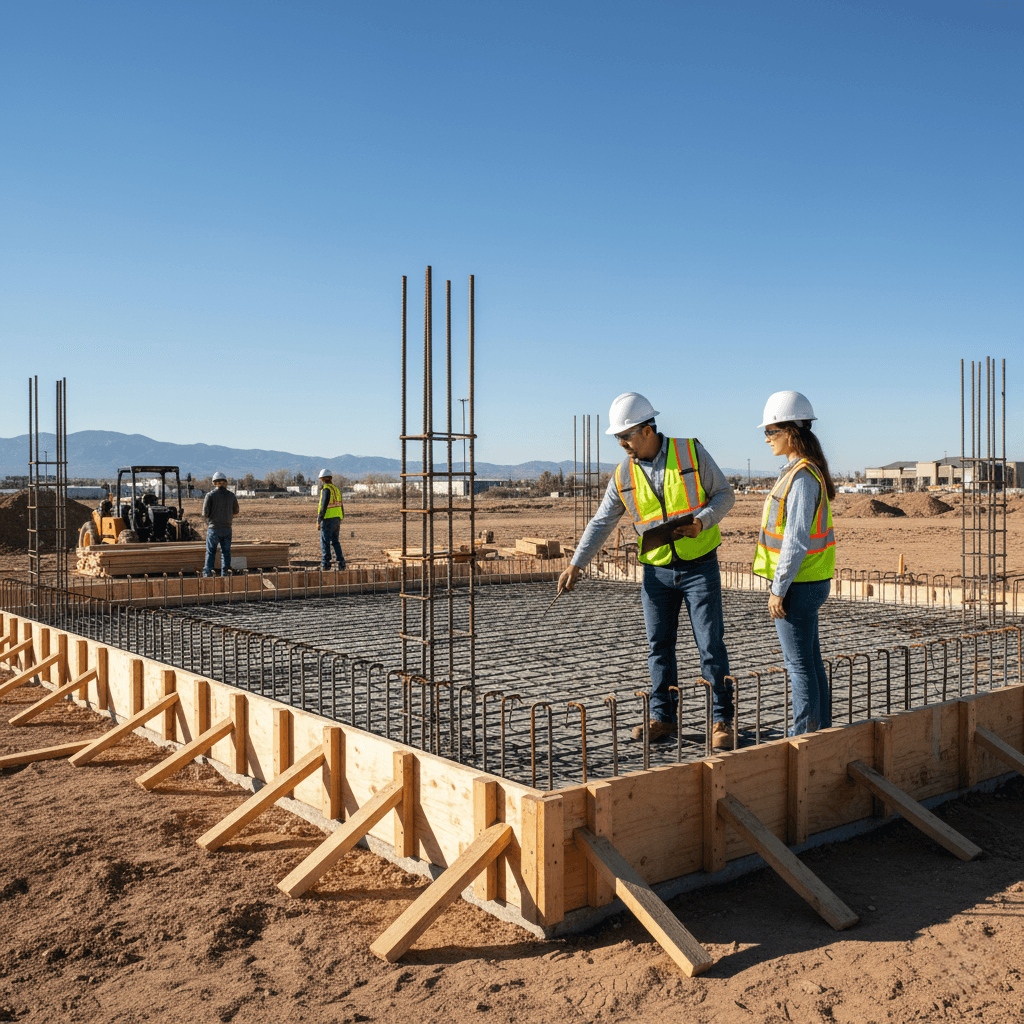

Deciding Whether to Postpone Repairs

While the pressure to perform repairs as soon as possible exists, some repairs must be postponed until the weather improves. Large-scale structural repairs, extensive resurfacing, and installation of new concrete require consistent favorable conditions to prevent costly failures. Performing these types of repairs in cold weather increases the risk of catastrophic failures that necessitate replacing the entire system. The cost associated with waiting for favorable conditions is less than the cost of failed repairs.

If you are going to perform repairs during the winter, look for multi-day periods with temperatures above freezing. Repair materials need 24 to 48 hours above 40 degrees to develop adequate initial strength. A single day of good weather followed by freezing temperatures will create problems for any recent repairs. Do not start any repairs if the forecast indicates temperatures will be below 40 degrees within 48 hours after completing the repairs. Take note of the overnight lows and daytime highs when planning your repair projects. Pueblo generally has cold nights followed by warmer days; however, arctic air masses can cause extended periods of below-freezing temperatures that require delaying repairs. We closely monitor multiple forecasting resources to enable us to make informed decisions regarding the best timing for winter repairs.

Temporary Emergency Repairs

When permanent repairs are not feasible due to the weather, temporary measures to prevent further damage can be implemented. Temporarily seal cracks with waterproof tape or plastic sheeting to prevent moisture from entering the crack. Redirect water flow away from damaged areas using temporary barriers or adjusting drainage. These emergency repairs are intended to prevent water from infiltrating the crack and causing freeze-thaw damage, rather than providing a permanent fix. Property owners in Pueblo will occasionally need to utilize these temporary fixes during severe winter conditions. We will implement the appropriate temporary repairs while we continue to plan for the comprehensive repairs that can be performed under more favorable conditions.

Leveling and Lifting Considerations

Leveling of concrete using mud-jacking or foam injection can be done in the winter months in Pueblo with proper precautions. It is the ground temperature that matters more than air temperature for these types of repairs. The substrate must be above freezing for the repair material to cure properly. Sunny days will warm the ground even when the air temperature remains cold.

Foam leveling is preferred over mud-jacking in cold weather since foam leveling develops its strength through chemical reaction, rather than just solidifying. The chemical reaction generates heat that assists in curing the foam despite cold temperatures. However, the ground can be so cold that it absorbs the heat generated by the reaction too rapidly to allow the foam to expand properly. We carefully evaluate the ground conditions prior to attempting leveling repairs in the winter. Residents of Pueblo residing in Skyview, West Park, and throughout the city can have their concrete leveled year-round when conditions permit.

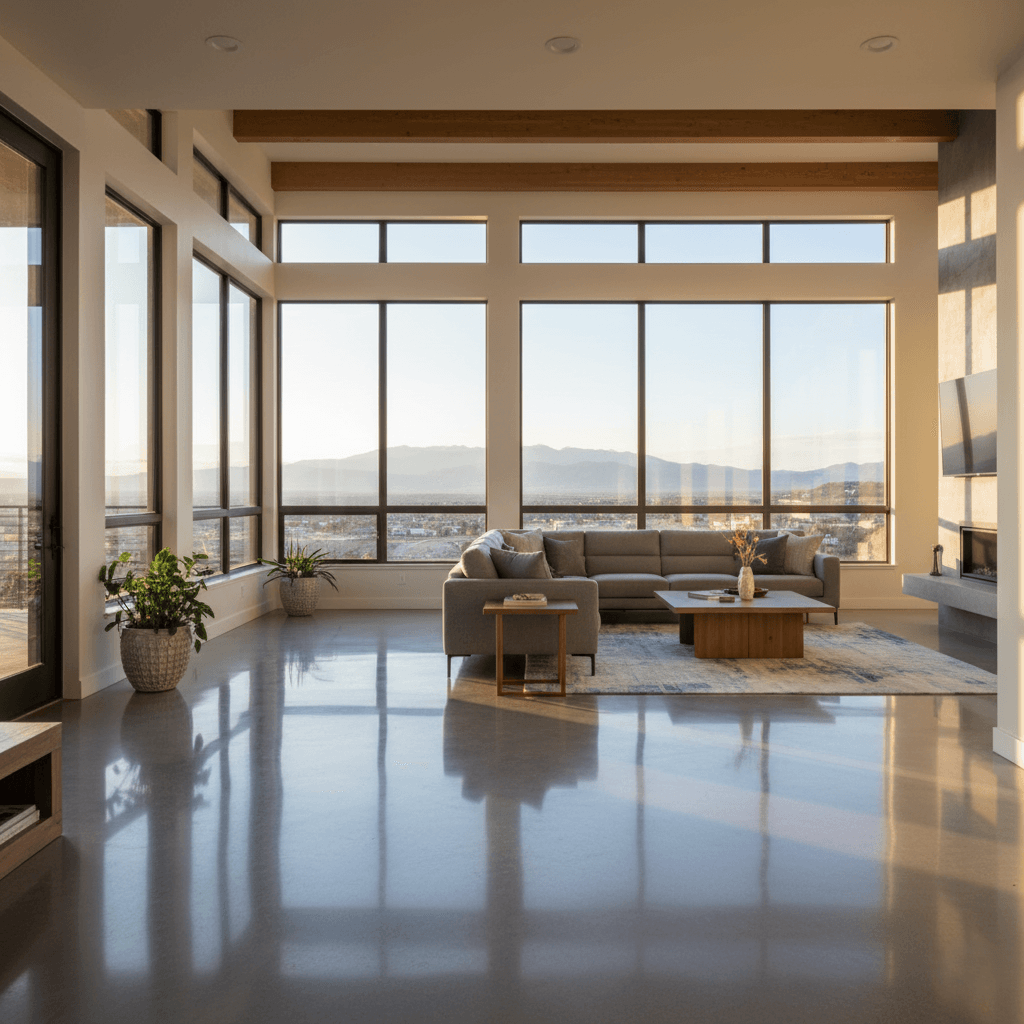

Interior Repairs

Repairs to basement and garage floors can be made at any time during the winter months since these locations are indoors and insulated, eliminating cold-weather concerns. Focus your winter repair efforts on interior repairs when the exterior conditions are unfavorable. Interior repairs require the same quality materials and techniques as exterior repairs; however, without the concern of weather conditions.

Scheduling exterior repairs for the spring, while performing interior concrete repairs during the winter, will allow you to utilize the majority of the winter months to complete repairs. Residents of Pueblo will benefit from having access to repair services year-round by prioritizing interior repairs during the winter months. We assist residents of Pueblo in developing a comprehensive repair plan that considers seasonal limitations.

Benefits of Hiring a Professional

Hiring a professional will help determine if the current weather conditions are suitable for repairs. Professionals assess the weather forecast, the type of materials needed for the repair, and the size of the repair to provide recommendations for the best timing. Because professionals understand the climate of Pueblo and its specific weather patterns, what may be suitable for repairs in other climates may not be suitable in Pueblo. Homeowners may be tempted to hurry and complete repairs despite the risk of failure. We provide honest evaluations of potential repair feasibility during winter consultations and provide recommendations for delaying repairs when it is in the homeowner’s best interest. Providing homeowners with reliable information based on decades of experience in Pueblo is a service we provide at minimal cost compared to the potential costs of failed repairs.

Preparing for Spring

Use the winter months to plan your major repairs to be completed in the spring. Obtain bids from potential concrete contractors, purchase any required materials, and schedule the contractor to begin repairs as soon as the weather permits. Planning will ensure that your repairs are completed quickly once favorable conditions exist. Spring is considered the peak season for concrete repairs in Pueblo; therefore, scheduling repairs in advance will provide you with an advantage.

Compile a list of all necessary repairs during the winter months and prioritize them according to their urgency and feasibility to be completed during the winter. Smaller repairs can be completed during favorable winter days, while larger repairs that require consistent favorable weather conditions are best scheduled for the spring. Residents of Pueblo will benefit from strategically planning their repairs to optimize their productivity. We will assist you in creating a comprehensive repair schedule that takes into consideration the limitations imposed by seasonal conditions.

Maintaining Concrete to Reduce Winter Damage

By maintaining your concrete before winter arrives, you can reduce the need for emergency repairs to be completed during the cold winter months. Seal cracks in your existing concrete in the fall to prevent water from penetrating into the cracks during the freeze-thaw cycle. Apply a quality concrete sealer to protect your concrete surfaces from moisture and de-icing salt damage. Clean your drainage systems to ensure water does not accumulate near your concrete structures.

Clear snow from your concrete surfaces as quickly as possible to prevent moisture from accumulating on the surface. Use plastic shovels to clear snow to prevent scratching the surface of the concrete. Keep proper drainage away from your foundation and slabs throughout the winter months. By taking these preventative measures, residents of Pueblo can minimize the number of emergency repairs required during the harsh winter months. We recommend a comprehensive fall maintenance program.

Making Informed Winter Repair Decisions

A successful cold-weather concrete repair is heavily based on knowing Pueblo’s unique climate, as well as which materials and methods to use, in addition to the strategic scheduling of your project. While many smaller repairs are completed with great success on the best winter days, larger repairs usually have to wait until spring to be done.

Protecting fresh repairs, avoiding deicing salts, and implementing temporary measures when necessary prevent winter damage from worsening. At Pueblo Concrete Services, we provide expert concrete repair services year-round, utilizing proven cold-weather techniques and materials when conditions permit, while honestly advising that postponing repairs serves homeowners better, ensuring quality results that protect your investment regardless of season.