Decorative Concrete: Microtoppings, Overlays, Stencils in Pueblo

Decorative Concrete Pueblo

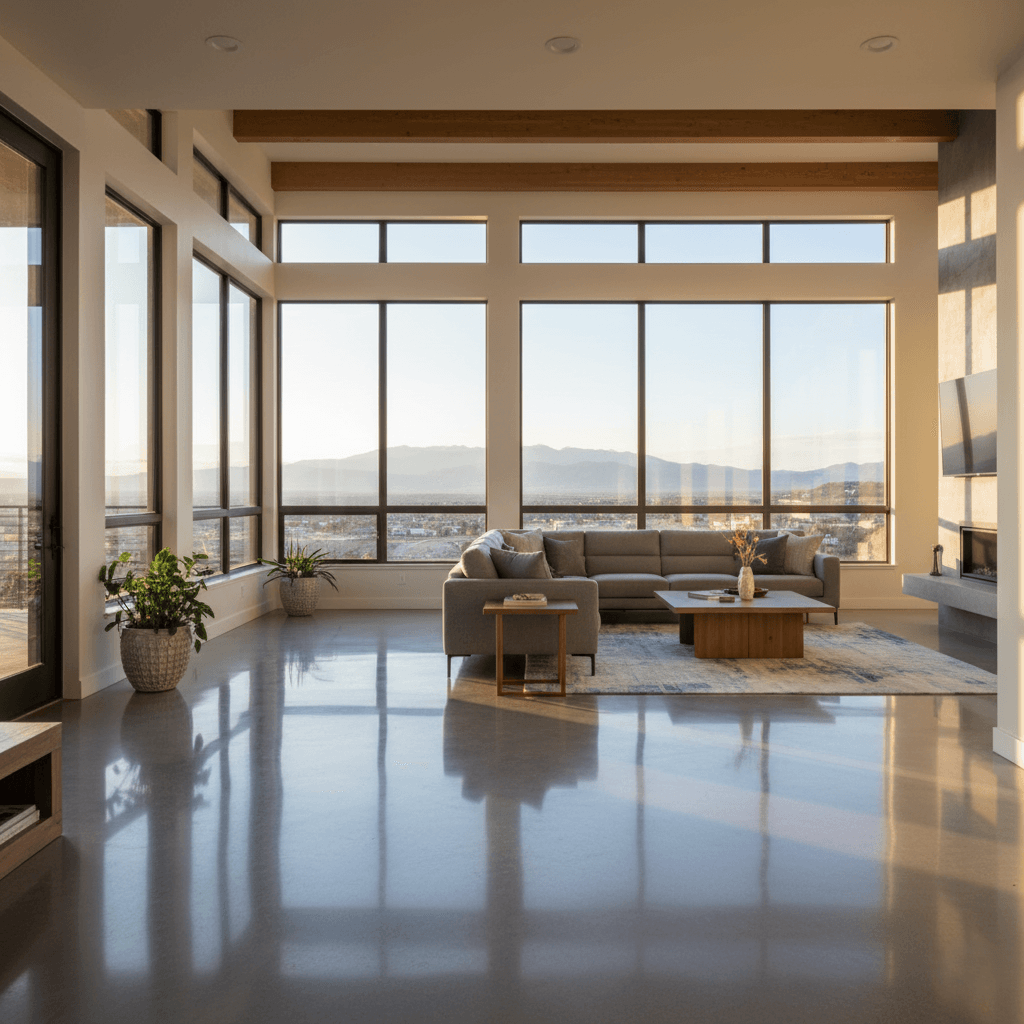

Transform outdated or damaged surfaces into stunning focal points without the expense and disruption of complete replacement. Modern decorative concrete techniques offer Pueblo property owners remarkable versatility for creating custom looks that rival natural stone, ceramic tile, or exotic hardwoods at a fraction of the cost. Whether renovating a worn commercial floor downtown or updating a residential patio in one of our established neighborhoods, these innovative systems breathe new life into existing concrete while providing durability that withstands our unique climate challenges. Understanding available options helps you select approaches that best match your aesthetic vision, budget constraints, and performance requirements.

What Is Microtopping and What Are Its Uses?

Microtoppings are thin (approximately 1/16″ to 1/8″) cementitious coatings applied to existing concrete to create uniform, smooth surfaces. They are modified with polymers and have many of the same characteristics as conventional overlays. However, their thinness allows for application to interior floors without greatly increasing the floor-to-ceiling height or significantly increasing the weight of the floor. This is especially beneficial for interior spaces where door clearances may be limited, or when the total load on a structure is already near maximum capacity. Additionally, their thin nature allows for the application of microtoppings to vertical surfaces such as walls, creating a sleek, contemporary look similar to Venetian plaster or other upscale finishes.

The versatility of microtoppings makes them different from other forms of traditional concrete resurfacing. Microtoppings can be troweled to create extremely smooth surfaces; they can be left with a slight texture to create visual interest, and they can be manipulated during application to create various artistic effects. In addition to natural grays and whites, microtoppings come in virtually limitless custom colors that can be created using integral pigments or topical stains once the product has cured. Areas such as Eden, CO, are able to take advantage of the fact that these very thin coatings can renew older, worn-out floors without having to go through the several-month process of demolishing and replacing flooring.

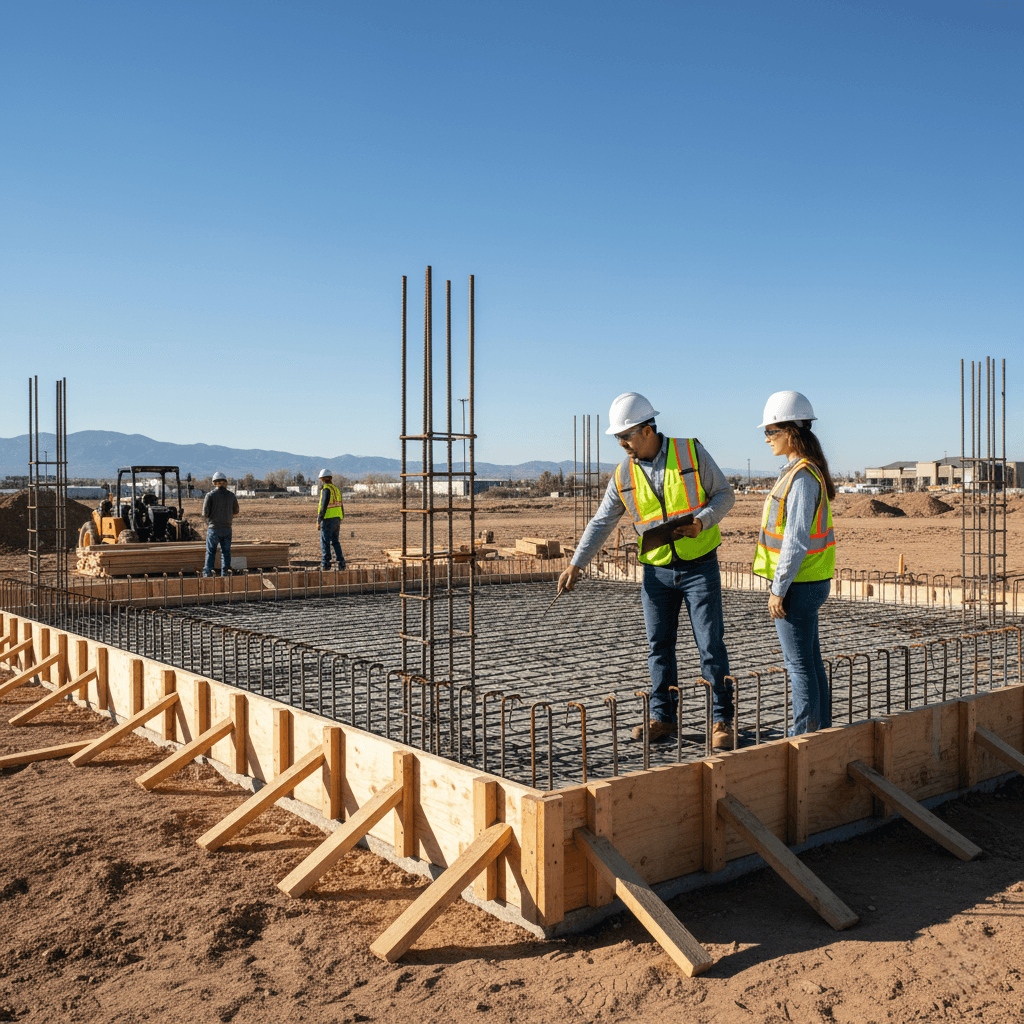

Preparation for Application of Microtoppings

The success of applying microtoppings to existing concrete surfaces relies heavily on the correct preparation of the surface. To ensure a strong bond between the original concrete and the new microtopping, the surface must be free from defects, thoroughly clean, and prepared with the correct profile to provide the required mechanical bonding. Contaminants must be removed, and the pores in the concrete must be opened to allow the thin layer of microtopping to form a solid bond to the surface. Grinding will accomplish this task and create the required surface texture for the thin layer of microtopping to grip the surface. All failed coatings, sealers, and curing compounds must be fully removed before the application of microtoppings, as even a small area of contamination will cause delamination and spread over time. Preparation of the surface is the most critical step in the process of applying microtoppings to a surface; however, many homeowners concentrate on the result and do not understand the significance of preparing the surface.

Comprehensive Overlay Systems

Thicker overlay systems that range in depth from 1/4 inch to 1/2 inch provide a solution to more serious concrete damage, while still being significantly less expensive than full replacement. Thicker overlay systems will repair minor cracks, level out uneven surfaces, and totally hide any discoloration or patchwork from previous repairs to the surface. The incorporation of polymers into the thicker overlay systems increases the flexibility, adhesion, and chemical resistance of the system compared to standard concrete, resulting in durable surfaces that can withstand foot traffic, extreme temperatures, and cleaning agents without deterioration. For businesses along the Riverwalk, overlays provide a way to restore high-traffic floors and maintain business operations during installation.

Self-Leveling Formulations

Self-leveling formulations make applying overlays to interior floors much simpler due to the fact that they flow easily across the surface of the floor and self-level through gravity. Self-leveling products are especially useful for larger open areas where troweling by hand would be a significant time consumer, and could potentially result in visible hand prints on the finished surface. There are also many other types of overlay systems available that can be applied by troweling, spraying, or rolling, depending on the type of texture and finish desired. Each of these application methods will produce different finished appearances, ranging from perfectly smooth contemporary finishes to rustic textured finishes that resemble aged materials. With the variety of overlay products available, you will be able to find an overlay that meets your needs for architectural style and function.

Decorative Treatment Possibilities

Newly applied overlay surfaces can receive several decorative treatments that will personalize your space and create visually appealing effects. Acid stains react chemically with the cementitious materials in the overlay to produce a wide array of natural earth tone colors that will vary slightly across the surface. Water-based stains provide a wider range of color options and include bright blue, red, and yellow colors that cannot be produced with acid staining. Dyes produce intensely colored, uniformly colored surfaces that penetrate deeply into the overlay. By combining various coloring techniques, you can create depth and complexity in the appearance of the surface that rivals natural materials, but at a fraction of the cost.

Stenciling for Custom Patterns and Designs

Stencils offer unlimited possibilities for creating custom patterns and designs on your floor. The possibilities for creating designs with stencils will turn plain surfaces into visually interesting designs that resemble tile, brick, stone, or other graphic designs. Stencils are used by applying adhesive-backed stencils to the surface of the floor, and then applying a coating or stain to the surface. Wherever the stencil is located on the surface, the treatment will not reach, and wherever the stencil is not located on the surface, the treatment will. Once the treatment is complete, the stencil will be removed, and the surface will resemble hand-laid tile, brick, or stone, but at a fraction of the cost and time involved in laying tile, brick, or stone. Many businesses on Union Avenue use stenciling to create custom floors that help create a recognizable image for their company, while still performing well under the demands of high usage.

Stenciling Options

There is a wide variety of stenciling options available, and they can be used to create designs that range from traditional brick and cobblestone layouts to contemporary geometric designs and organic stone arrangements. The stenciling options available can be used to create borders, medallions, and custom logos that will add a personal touch to your floors that mass-produced materials cannot match. There are three primary ways to apply stencils to your floors, and each method will produce a different effect: overlay stenciling will create raised, embossed patterns in your newly applied coatings; acid-etching will create recessed patterns in your coatings that resemble tile grout lines, and sandblasting will carve patterns directly into your existing concrete. Each method will produce a different effect that will depend on the type of design and the appearance you want to create.

Application Techniques and Considerations

Adhesive-backed stencils make applying stencils easier because the adhesive backing stays firmly attached to the surface of the floor during the coating or staining process, and prevents any of the treatment from bleeding underneath the edges of the stencil, thus keeping the pattern lines crisp and visually appealing. Paper stencils offer a cost-effective option for projects that require only one set of stencils. Plastic stencils are reusable and can be used again and again until the stencil eventually wears out. Regardless of the type of stencil you choose, it is essential to position the stencil correctly on the floor before beginning the coating or staining process, as moving the stencil once the coating or staining process has begun will likely damage the stencil and the partially completed surface. Careful planning of your stencil layout will help prevent awkward cuts at walls and transitions between rooms.

Interior Applications

Residential spaces greatly benefited from the use of decorative concrete techniques that will update the appearance of your home’s finishes without the disruption of major construction. Elegant floors for living rooms, kitchens, and dining rooms can be achieved with decorative concrete finishes at a lower cost than using hardwood or tile, and with better durability. Residential basements can be transformed from cold, gray storage areas to warm, inviting living areas by polishing or staining the concrete surfaces, which also provides moisture resistance and a sophisticated appearance. Homeowners in the Lincoln Park area of Denver, CO, have discovered how decorative concrete eliminates the cold, gray concrete look while retaining the benefits of easy cleaning and allergen resistance.

Moisture-resistance is a particular benefit for bathroom and laundry room surfaces that are subject to constant moisture. Wood floors warp and carpet absorbs mildew, whereas sealed decorative concrete surfaces repel water and provide slip-resistance through textured finishes. Radiant heat systems can be integrated into thin decorative concrete overlays, providing comfortable heat in Pueblo’s cool winters without compromising the decorative appearance. These combinations of radiant heat systems and decorative concrete provide spa-like environments in master bedrooms or functional efficiency in utility areas, demonstrating the versatility of decorative concrete in a variety of residential applications.

Commercial and Retail Spaces

Property owners are also appreciative of decorative concrete’s ability to create impressive spaces while managing renovation budgets. Decorative concrete can be used to create custom floor patterns that direct customer flow and establish merchandise zones without the need for permanent walls. Restaurants use decorative concrete to create durable, stain-resistant overlays that can withstand the wear and tear of heavy traffic and spills, while matching the restaurant’s interior design theme. Office buildings near the Sangre De Cristo Arts Center can install polished microtoppings to create contemporary environments that make a good impression on customers, while requiring little to no maintenance compared to carpet or vinyl.

Durability in high-traffic areas makes decorative concrete a practical choice as opposed to simply an aesthetic choice. Decorative concrete can withstand years of foot traffic without exhibiting wear patterns that would necessitate refinishing or replacement. Decorative concrete is resistant to cleaning agents and accidental spills that occur in food service or industrial settings. Decorative concrete is also resistant to abrasion caused by the movement of equipment or dropped objects. These performance characteristics assure long-term value while maintaining aesthetically pleasing appearances that are representative of the business’s operation.

Exterior Concrete Transformations

Outdoors, decorative concrete treatments can also enhance outdoor spaces. Patios and pool decks can have slip-resistant textured finishes combined with attractive colors that complement landscaping and architectural elements. Driveways can be transformed from plain gray expanses to welcoming entrance areas through the use of stamped patterns or stenciled designs. Walkways adjacent to properties similar to those around Dutch Clark Stadium can be treated with decorative finishes that enhance curb appeal and provide safe, durable pedestrian surfaces through all seasons.

Decorative concrete treatments are essential in Colorado, where surfaces are exposed to intense UV radiation, extreme temperature fluctuations, and occasionally moisture from rain or snow. Exterior products should be formulated to contain UV stabilizers to prevent color fading, air entrainment to protect against free-thaw damage, and sealers that repel water while allowing vapor transmission. These engineering considerations will ensure that the decorative concrete treatment will perform similarly to or better than standard concrete while providing substantially improved aesthetics that will increase property value and owner satisfaction.

Maintenance and Durability

Proper maintenance will keep decorative surfaces looking great for decades. Regular sweeping or dust mopping will remove dirt and debris that may scratch or abrade finishes. Periodic damp mopping with a pH-neutral cleaner will help to maintain the appearance of the surface without damaging the sealers or coatings. Re-sealing frequency varies depending on the amount of traffic and exposure to elements, and generally occurs every 2 years for high-traffic commercial areas and every 5 years for residential areas that are protected from the elements. When comparing the low maintenance requirements of decorative concrete to alternatives that require frequent refinishing, waxing, or replacement to maintain an acceptable appearance, decorative concrete is clearly a more desirable option.

Comparing Costs and Evaluating the Value of Decorative Concrete

Budgetary limitations play a significant role in determining the selection of materials used in decorative concrete applications, and therefore, cost-effectiveness is a significant consideration along with aesthetic appeal. Microtoppings and overlays typically cost significantly less than removing and replacing concrete, and provide a much greater visual improvement than basic resurfacing. Adding stenciling to plain overlays will increase the overall cost, but it will still be significantly less expensive than hand-laying tile, brick, or stone to create the same custom patterns and designs. As the size of the project increases, so does the cost difference between decorative treatments and alternative materials.

When evaluating long-term value, decorative systems demonstrate a clear preference over other decorative systems. Decorative systems have the potential to last for decades without needing replacement, thereby eliminating repeat renovation costs that alternatives incur. The low maintenance demands of decorative systems will continue to decrease ongoing labor and material expenses. Decorative systems also exhibit energy-efficient qualities due to the thermal mass of the material and the reflective finishes, thereby decreasing the amount of energy needed to heat and cool a structure over the course of its lifetime. Property owners in neighborhoods such as Belmont East recognize that their initial investments in decorative systems yield returns through years of reliable performance and continued aesthetic appeal.

Design Versatility and Customization

There are creative possibilities that extend far beyond selecting colors for decorative concrete. Property owners can select from a wide variety of customization options to create personalized spaces that reflect their own taste and functional requirements. Techniques can be combined to create multi-layered effects that are unattainable through the use of single technique applications. A combination of dye base coats and contrasting stenciled patterns can create dimensionally deep appearances with visual interest. Scored lines can be used to divide large areas into smaller areas that resemble planks, tiles, etc., and can be used to create geometric patterns. Metallic pigments can be added to create shiny, light-catching effects that change as the viewing angle changes. These combinations of techniques and materials will enable you to transform ordinary concrete into artistic statements that serve as the focal point of the room, rather than just a functional surface.

Consistency with Surrounding Materials

Decorative concrete can be matched to the colors and/or architectural styles of the surrounding materials to create a cohesive design throughout your property. Overlays can be created to match the colors of surrounding tile work, countertops, or exterior stone. Patterns can be selected to match furniture styles, from traditional brick and cobblestone patterns to modern geometric designs and organic stone arrangements. Decorative concrete is versatile enough to be used across a wide range of architectural styles and personal preferences, which explains its growing popularity among Pueblo residential and commercial property owners.

Professional Installation Benefits

Many homeowners are aware of the many decorative options available in today’s market, but what is often misunderstood is that truly professional-looking decorative finishes require extensive experience, numerous pieces of special equipment, and a deep understanding of how different materials will perform when applied under various temperature and humidity conditions. The curing time of many materials can be affected by these environmental conditions, as well as the amount of material mixed at one time (thickness) and when it was applied. Many homeowners have been left with a poor finish due to improper application techniques and/or equipment operation and maintenance. Professional installers have the benefit of having done literally hundreds of jobs, which allows them to eliminate the trial and error process that can result in wasted materials and less than satisfactory finishes.

In addition to their experience, the cost of purchasing and maintaining equipment used in decorative concrete finishing can be an expense many homeowners cannot afford. Decorative concrete finishing equipment includes grinders, sprayers, trowels, and finishing tools. While these items may be used on occasion for decorative applications, they are not frequently used enough to justify the high cost of purchasing new ones each time. In addition, safety issues such as dust control, safe handling of chemicals, and adequate ventilation are major concerns for professionals who are working with hazardous materials on a regular basis. These reasons contribute to the fact that most successful decorative concrete projects are completed by experienced contractors, even though there are numerous do-it-yourself decorative concrete products and instructions available to homeowners.

Decorative Concrete Solutions for Your Pueblo Property

Regardless of whether you want to give your home or business a fresh look or completely transform its appearance, decorative concrete provides endless possibilities for both style and budget. At Pueblo Concrete Services, our staff has years of experience and knowledge in applying all types of decorative concrete finishing techniques, including micro-toppings (a very thin layer of decorative concrete) to complete overlay systems. We provide custom designs using a variety of stencils to create unique and intricate designs that are difficult, if not impossible, to achieve using other decorating techniques. We treat every job individually and ensure that the surface is properly prepared before applying the decorative finish. Additionally, we apply a protective sealant to protect your decorative finish from the extreme weather conditions found in the Pueblo area.

We assist you in making the necessary decisions regarding your design, selecting the right materials, and providing you with realistic estimates regarding the timeframe to complete your job. As a local company with numerous successful decorative concrete finishing projects behind us, we are confident that we can help you achieve your decorative concrete goals for either your residential property or commercial facility in the Pueblo area.