Pueblo Concrete Pouring Tips: Correct Slump & Mix

Pouring Concrete Pueblo

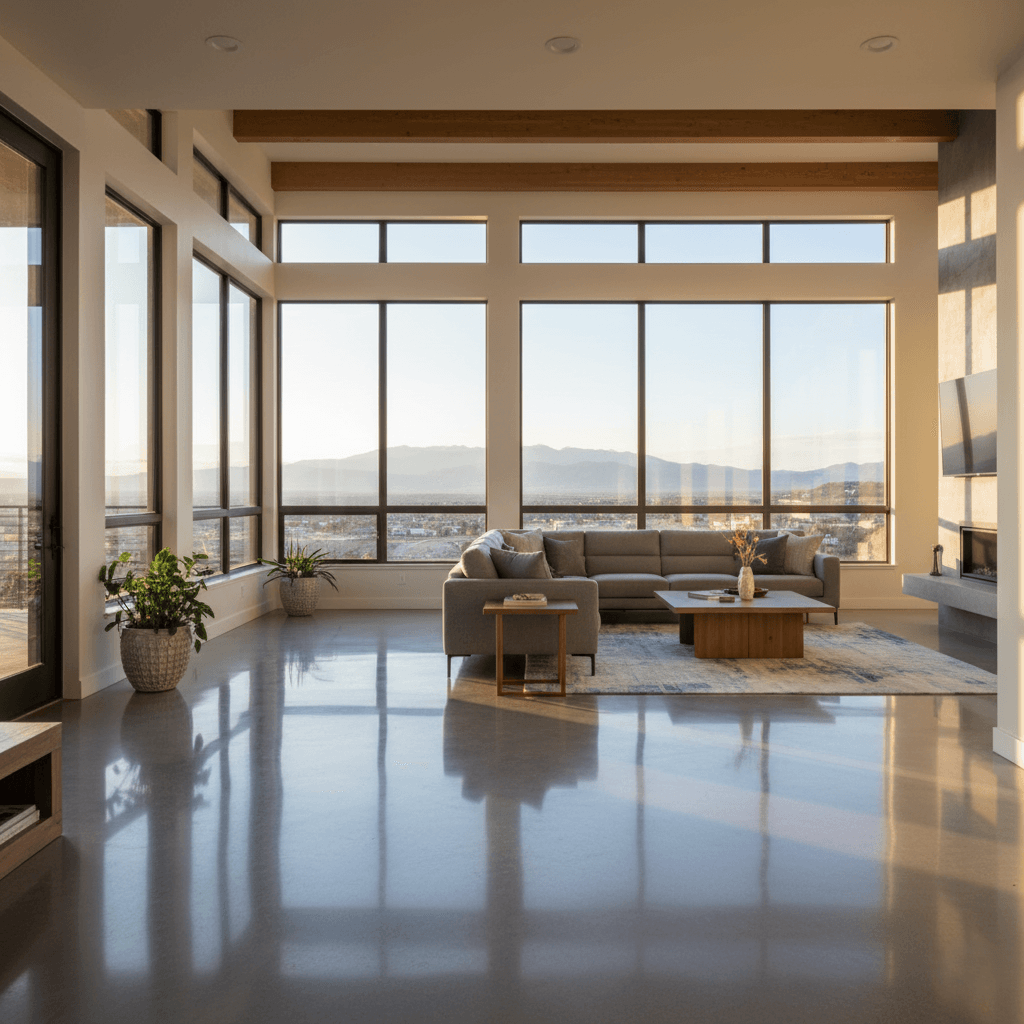

Achieving the right concrete consistency makes all the difference between a durable, long-lasting installation and one that develops problems down the road. Whether you’re working on a residential driveway near City Park or a commercial foundation in the Union Avenue Historic District, understanding slump values and mix proportions ensures your project meets both local requirements and industry standards. Proper testing and mix design protect your investment while complying with Pueblo’s building regulations.

Understanding Concrete Slump and Why It Matters

The slump test is used to determine the workability of freshly mixed concrete before placement. By performing a simple test, you can determine if the water-to-cement ratio of the concrete being delivered to you is correct for your particular use. Contractors throughout Colorado rely upon the ASTM C143 Standard Test Method for Slump of Hydraulic-Cement Concrete, as well as other industry-related standards, to ensure quality control of their projects.

When conducting a slump test, the concrete is placed into a 12″ cone in three layers (each layer is 4″ deep) and then tamped 25 times with a steel tamping rod. Once the cone is removed, the amount of settlement of the concrete is measured by determining the difference between the original height of the cone and the current height of the settled concrete.

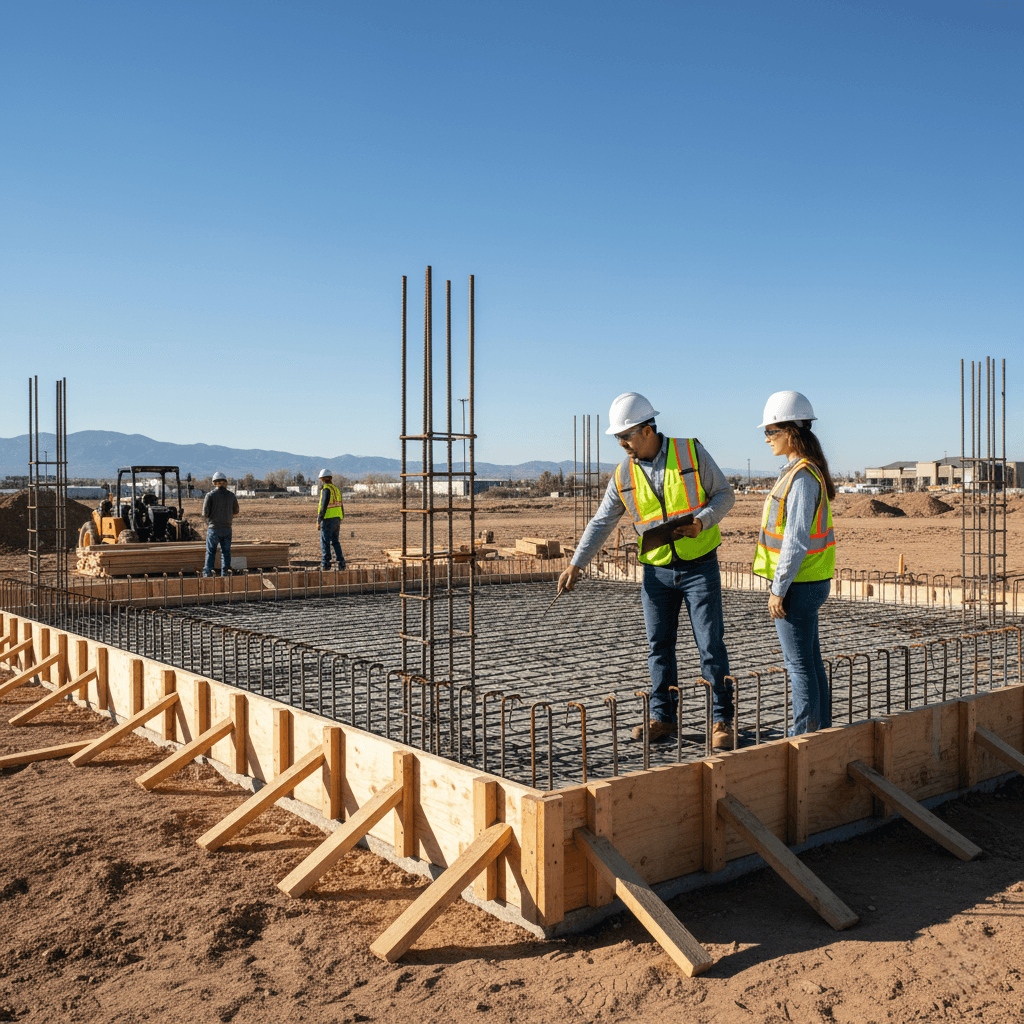

There are many types of concrete projects that take place in Pueblo, and each type of project requires a certain range of slump values. For example, foundation work typically requires low-slug (typically between 2 and 4″) because this will allow for maximum structural integrity of the foundation. Wall and vertical construction typically works best with a medium range of slump values (typically between 4 and 8″), and allows for easy placement of the concrete while providing enough strength to support the walls and structural components. Driveways and Patios in proximity to the Historic Arkansas River Walk typically work best with a slump value between 3 and 5″.

These values are not arbitrarily selected: they directly relate to the final strength and durability of your finished product.

Local Regulations and Permits

Most concrete work that takes place in the city right-of-way requires permits. A homeowner can get a permit to install a sidewalk adjacent to their property; however, a licensed contractor will be required to install a curb and gutter system. The Pueblo Regional Building Department will oversee and ensure compliance with all applicable building codes and regulations.

Projects that take place on private property may also require permits, depending on the nature and extent of the project, such as, but not limited to, foundations, structural components, and major flatwork installations.

By understanding the regulations prior to beginning your project, you will eliminate potential delays and fines. The permitting process typically takes a few business days to complete; therefore, planning ahead of time will keep your timeline intact. Licensed contractors who are familiar with the local regulations will significantly assist with the permitting process.

Our company is fully bonded, insured, and licensed, and we comply with all city and county regulations for every project we complete from beginning to end.

Designing a Proper Mix for Pueblo’s Climate

Due to the unique climate conditions of Pueblo and the high altitude, along with extreme temperature fluctuations, designing a proper mix for the area is essential. The average annual sunshine hours in Pueblo iaregreater than 300 days per year, thus affecting curing times for concrete differently than in more humid climates. In addition, summer temperatures in Pueblo can reach above 90 degrees Fahrenheit, whereas winters in Pueblo are often characterized by freezing temperatures.

Therefore, the proper design of a mix for the area must consider water-to-cement ratios, admixture selection, and curing methods. A typical mix design for the area would include air entrainment to protect against free-thaw damage, especially for exterior applications located near Lake Pueblo State Park or in exposed areas throughout the county. Additionally, the water-to-cement ratio must be balanced between workability and strength, typically falling between 0.40 and 0.50 for most residential applications. A higher water-to-cement ratio will produce a more workable mix, but at the expense of final strength and increased permeability, resulting in potential moisture problems and reduced life expectancy of the concrete.

Selecting the Correct Aggregate

The selection of the aggregate will greatly affect the workability and final strength of the concrete. As a result of this, selecting the appropriate material from a local supplier is crucial, as they have materials specifically developed to withstand the extreme temperature fluctuations of the area. Larger aggregates typically should not exceed 1.5 inches for standard slump testing procedures. The fine aggregate must be free from excessive silt or organic materials that can potentially impede bonding.

Accurately Conducting Slump Tests On-Site

It is imperative to conduct slump tests within five minutes of obtaining a representative sample of your concrete to achieve accurate results. To perform the slump test, you will require the following equipment: a standard slump cone measuring 12 inches tall with an 8-inch bottom diameter and a 4-inch top diameter, a 5/8-inch diameter tamping rod with a hemispherical tip, a flat non-absorbent base plate, and a measuring device marked in quarter-inch increments. All equipment must be thoroughly cleaned and maintained between tests.

To minimize friction, the inside of the cone can be dampened. Fill the cone with the concrete in three equal layers by volume, not height, with each layer receiving exactly 25 tamps across the surface of the layer. The tamping rod should be able to penetrate approximately one inch into the previous layer for the second and third layers. After the third layer is filled, strike off any excess concrete so it is flush with the top of the cone. Remove the cone in a smooth, steady motion, taking approximately two to five seconds to allow the concrete to settle naturally.

Record the distance from the original height of the cone to the center of the settled concrete mass to the nearest quarter inch. The total time for the test, from beginning to end, should not exceed 2.5 minutes. Different slump profiles represent different conditions, including: true slump, indicating even settlement and a symmetrical shape, shear slump, indicating the top half of the concrete has slid to one side and indicates poor cohesion; and collapse slump, indicating excessive water content and immediate adjustment to the mix before placing the concrete.

Common Problems and Solutions

Several common problems may occur during testing and placement of the concrete. If the slump test indicates excessive slump, this typically indicates there is too much water in the mix, which decreases the ultimate strength and increases the potential for cracking. Increasing the amount of cement without increasing the amount of water will help alleviate this problem; however, this method will increase costs. A zero slump condition typically indicates either a lack of water in the mix or improper mixing, and makes finishing and placing the concrete very difficult. Small adjustments to the water content of the mix, while closely monitoring the consistency of the mix, will resolve this problem without decreasing the ultimate strength of the concrete.

Segregation of the aggregate particles from the cement paste is another common problem encountered during slump testing. Segregation of the aggregate particles from the cement paste is typically caused by excessive vibration or incorrect mix proportions. Changing the aggregate particle distribution or using air-entraining admixtures will typically solve segregation problems.

Temperature Extremes also Affect Concrete Performance

Extreme temperatures also affect concrete performance. High temperatures cause the concrete to set rapidly and may require retarders to slow down the setting process. Conversely, cold temperatures decrease the rate of hydration and may require heating the water in the mix or using accelerators to speed up the hydration process.

Troubleshooting During your Pour

Monitoring your concrete throughout the placement process will identify any problems that may develop before they become severe. Visual inspections of the color of the concrete loads will provide evidence of whether the loads are consistent in color, which should remain consistent throughout the pour. Variations in the color of the loads may indicate differences in water content or materials. Observing the characteristics of the finish of the concrete will also provide valuable information: if the concrete is difficult to float or finish, the slump may be too low, while bleeding excessively is indicative of too much water content.

Best Practices for Achieving Quality Results

Achieving success begins with proper planning long before the first truck arrives. Preparation of the site includes: clearing the area of any organic debris, properly compacting the sub-grade, installing adequate drainage, and verifying that the forms are level and securely fastened. Properly preparing the site will eliminate potential settling problems and allow for proper placement of the concrete. Monitoring the weather will enable you to select the optimal date(s) for pouring concrete; avoid pouring concrete when the forecasted temperature will be less than 40 degrees Fahrenheit within 48 hours, or when the temperature will be more than 90 degrees Fahrenheit during placement.

Communication with your Ready-Mix Supplier Establishes Clear Expectations

Clear communication with your ready-mix supplier will establish clear expectations of what your mix design and slump specifications are, as well as the expected delivery time(s), and any special requirements such as fiber reinforcement or colored concrete. Clearly defining the requirements of your project will prevent misunderstandings that could negatively impact your project.

Having sufficient personnel on-site will also facilitate rapid and effective placement of the concrete; concrete waits for no one, and having insufficient personnel will lead to rushed finishing and/or setting problems.

Quality Control Does not Stop with Slump Testing

While slump testing is an important part of quality control, it does not represent the totality of quality control measures. Additional quality control measures include: temperature monitoring, air content testing for exterior applications, and collecting compressive strength test cylinders to provide a comprehensive quality assurance program. While these additional quality control measures are relatively inexpensive compared to the cost of repairing failed concrete, documentation of all test results will protect both the contractor and property owner in case of future disputes.

Experienced Professionals Will Eliminate Guesswork

Using experienced professionals will remove all guesswork from your concrete project. Our team understands how the unique environmental conditions of Pueblo affect the performance of the concrete. We have completed numerous concrete projects in various locations in Pueblo, including the Sangre De Cristo Arts District and in neighborhoods near the Pueblo Zoo, while consistently adhering to the highest standards of quality. Every project we complete, regardless of its size, will receive the same level of attention to detail.

Proper slump and mix design constitute the foundation for quality concrete work. From the initial planning phase through the final finishing phase, every action taken will contribute to producing durable and aesthetically pleasing concrete installations that will provide years of service to property owners.

Pueblo Concrete Services combines decades of collective experience on every project we undertake. Our dedication to proper testing procedures and quality materials ensures your concrete installation will exceed your expectations. We will take care of all permitting requirements, and we are fully bonded, insured, and licensed, and we stand behind all of our work with comprehensive warranties. Whether you are constructing a new home near the Steelworks Museum or repairing existing concrete in an established neighborhood, our knowledge in pouring concrete will guarantee you receive professional results that will last.